|

|

|

|

|

|

|

|

|

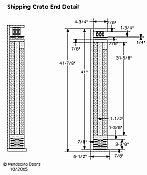

I design the case to fit the door(s), jambs and

hardware

|

|

I lay out all the pieces to fit tightly and well

padded

|

|

We start out by cutting strips of 1" and 1-1/2"

styrofoam

|

|

Then we wrap and seal each door in 4 mil

plastic

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here I set a "bed, placed the jambs on the bottom

........

|

|

..... then laid in the first door

|

|

.... then added a layer of 1-1/2" foam

........

|

|

........ and then laid in the second door.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

I designed the case to accept the hardware and

screws on the end.

|

|

The outer layer of foam is adhered to the sealed

door

|

|

Then the case is closed up and screwed together ....

every 6"

|

|

Lastly ... we add feet for a fork lift and

transportation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

We build our cases .......

to make the trip

|

|

Then we sneak it out of the shop.

Everything around here ...... is a custom

fit.

|

|

and slide the case out the "loading ramp" and onto

my trailer

|

|

It's sprinkling today, so we keep the case

covered

|

|

|

|

|

|

|

|

|

I live about 7 miles from the Pacific Coast, on the

edge of a 30000 acre Redwood state forest

|

|

|

|

|

|

I ship through Al Lewis trucking who transfers my

doors to TransGroup trucking in South San Francisco and from

there ......

the world !!

|

|

|

|

Now I wait for the trucking company to call and I'll

drive down to Hwy. 1

|

|

........... and we load 'er up ....... and off go

the doors to Hawaii !!

|

|

|

|

|

|

|

|

|

|

|