|

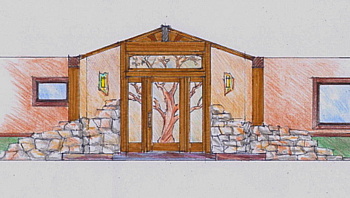

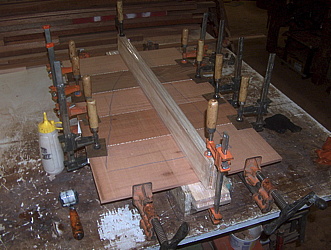

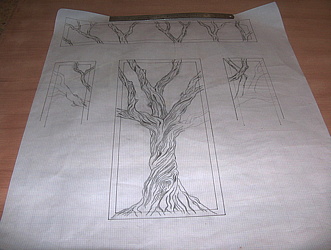

This is The Simcha Grand Entry The Door, Sidelights, and Transom are all vertical grain Ribbon Grain Mahogany with a overlaid Hand Carved Tree of VG Redwood Laminate The Carving is by Ken Davis of Mendocino The Door is 42" x 84" x 1-3/4" with 2 - 22" sidelights and a 20"(high) transom above |

|

||||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

||||||||||

|

Below is the provenance of the making of this grand entry |

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|||||||||

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

||||||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

|

||||||||

|

|

|

|

||||||||

|

|

|

||||||||

|

|

|

|

|

|||||||

|

|

||||||||||

|

|

|

||||||||

|

Now they dry and wait for the next oiling. |

|

|

||||||||

|

|

||||||||||

|

|

|||||||||

|

The transom |

|

|||||||||

|

|

||||||||||

|

|

|

|||||||||