|

|

|

|

|

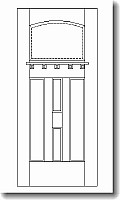

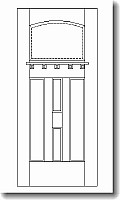

Here is the proposed Door drawing

|

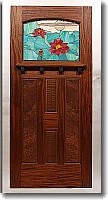

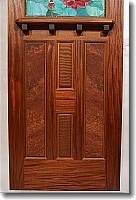

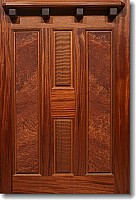

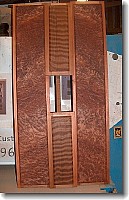

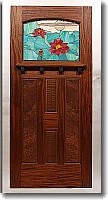

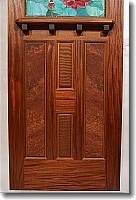

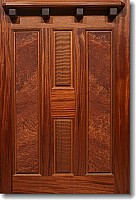

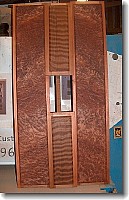

How'd I do ? Here is the completed door

|

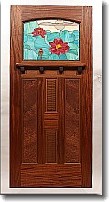

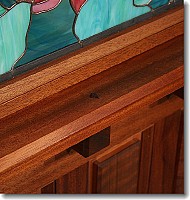

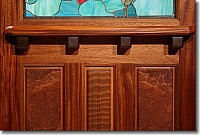

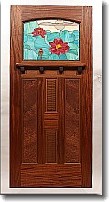

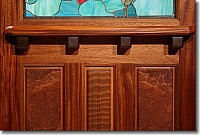

A close-up of the top portion of the door

|

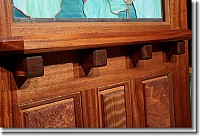

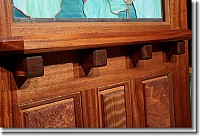

Another view

|

|

Click on Any

Image to Enlarge

|

|

|

|

|

|

Here is a backlit view of the stained glass

|

This Entire door, dentil shelf, and dentil

posts came from

this ONE slab of Mahogany ..... amazing wood

|

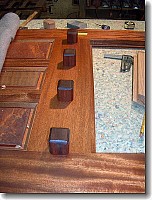

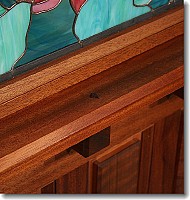

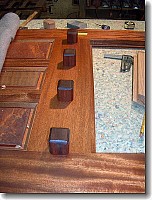

The dentil shelf is attached with stainless steel screws,

capped with CocoBolo square caps

|

|

|

|

|

|

|

|

|

|

The panels are bookmatched Old Growth Redwood Burl on the

out side

|

and Old Growth Curly Redwood for the center panels

|

Here is a closer view

|

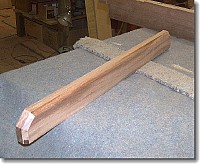

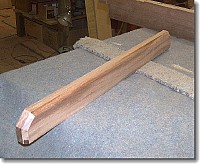

The dentil shelf and posts came from the same plank used

in making the door

|

|

|

|

|

|

|

|

|

|

|

|

|

Here is the History

of how this door was constructed

|

|

|

|

|

|

|

Here are the "ruffed" out pieces allowed to settle

down before machining

|

Here are some of the pieces after being joined flat

and then rough planed

|

Then All of the pieces have to be dimensionally

sanded because the grain is so figured (ribbon grain) it has

to be sanded to thickness

|

The the machining begins

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Here I cut the arch for the window

|

........ and the plane it to a perfect arch with an

antique Compass Plane

|

Then we start gluing and "build" the door from the

inside out

|

Here is the door being turned to clean the other

side

|

|

|

Click on Any

Image to Enlarge

|

|

|

|

|

|

|

......... just look at the figured "ribbon

grain"

|

Here the door will stay in clamps for at least 3

days

|

Here is the door fresh out of clamps

|

Here I am making the ply template for DragonEye to

use to make the beautiful stained glass window

|

|

|

|

|

|

|

|

|

|

The entire door is the machine sanded to a furniture

finish

|

Here are the panel blanks .... All

bookmatched Old Growth Redwood Burl

|

Here is the panel sub straight. It is marine grade

plywood, edged with old growth Redwood

|

Here are some of the figured center wood in

clamps

|

|

|

|

|

|

|

|

|

|

Here are the panel blanks coming out of "speedy" my

sander .... "speedy" is very slow ..... but does a wonderful

job

|

Here the chamfered raised panel is hand

sanded

|

Here are the oiled panels .... they will have 4

coats of varnish oil before they are installed

|

Here is the dentil shelf ....... from the same plank

at the top of the page

|

|

|

|

|

|

|

|

|

|

Since I make all my doors oversize, I then have to

re-cut the door to the correct length and width

|

After planing the edges ..... I mortise for the

hinges

|

Here is a mortised bronze ball bearing hinge and my

"signature" on the door

|

All of the molded edges are hand sanded to a 220

grit finish

|

|

|

|

|

|

|

|

|

|

Then the door is varnish-oiled for 4 coats

|

Look at the magnificent grain

|

It is called "ribbon grain"

|

The door cures at least 3-4 days between all four

coats of varnish-oil

|

|

|

|

|

|

|

|

|

|

Here are all the stops cut

|

and then the stops are installed with stainless

steel fasteners and the excess caulk is cleaned up

|

Here is the finished product

|

Here we are making our custom jambs. they are made

by laminating two 3/4" pieces of Mahogany ...... this makes

for an extremely stable jamb

|

|

|

|

|

|

|

|

|

|

Here they are being oiled (on all

sides) with our varnish~oil

|

Here are the dentil posts being oiled ..... 4

times

|

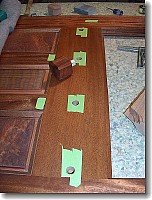

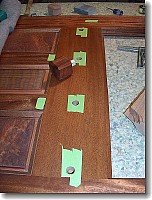

Here I am laying out the dentil post

placement

|

And then they are clamped in unison to the

door

|

|

|

|

|

|

|

|

|

|

How'd I do ??

|

I then layout the placement of square pins that will

attach the shelf to the posts

|

Phew ......... it fits !!

|

Here we "bed" the class and cut and install the

Mahogany stops.

|

|

|

|

|

|

|

|

|

|