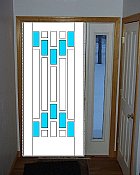

I call this door

"The Cape"

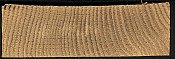

This door is made of quartersawn White Oak

It is 40" x 80"

and is now "living" in Cape Cod

|

|

|

|

|

|||

|

|

|

|

|

|||

Click Here to View the Installation of The Cape

|

|

|

||

|

|

|

|

||

|

|

||||

|

|

|

|

||

|

|

|

|||

Return To Gallery

Here is the history of the construction of The Cape

Click on ANY Image to Enlarge

|

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

It took 4 hrs to assemble and clean this beautiful door |

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

||||||

|

|

Here is the 4th and last coat of varnish oil |

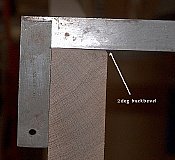

We are still waiting for most of the glass ........ but we have stared cutting the 186 individual miters in this door |

Here are some pictures of the 3/4" thick, hand beveled, Diamante Starfire |

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

||||||

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

||||

|

|

||||||

|

|

|

|||||

|

The last wall is screwed on to the frame and the door is ready to make its journey across the country |

||||||

Return To Gallery