|

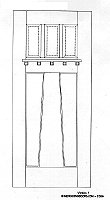

It is constructed out of Genuine Mahogany The door is 42" x 94" x 1-3/4" The sidelights are actually 13" x 94" x 1-3/4" The glass with be beveled, tempered, and insulated The panels will also be Genuine Mahogany |

|

|

|

|

||

|

|

|

|

||

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

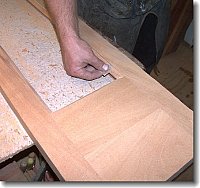

Time to finish sand and trim |

Then oil with 4 coats of varnish |

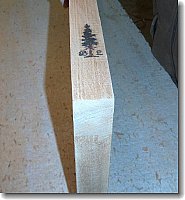

Here are the jamb pieces curing before hanging the door and sidelights |

||

|

|

||||

|

|

||||