|

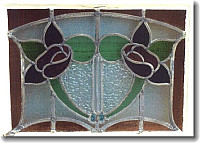

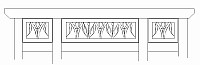

This Entry is called The Arlington It is Old Growth Redwood with figured Redwood panels With a 42" x 80" Redwood door with 2 ~ 16" sidelights and a 3 piece transom of stained glass The clear glass is art glass called Seedy Reemy |

|

|

|

|||||||

|

|

|

|

|||||||

|

|

|||||||||

|

|

|

|

||||||

|

|

|

|

|

||||||

|

|

|||||||||

|

|||||||||

|

|||||||||

|

|

|||||||||

|

|

|

|

||||||

|

|

|

|

|

||||||

|

|

|||||||||

|

|

|||||||||

|

|

|||

|

|

|

|

|

AND ..... NO LIVE TREES were cut in the making of this amazing lumber |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

"Seedy-Reemy" art glass |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||