|

|

|

|

|

|

|

|

|

|

I "final dry" all wood in a wood heated

environment.

|

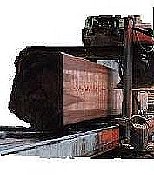

Salvage logs being milled by local independent

sawyers

|

Check out the growth rings !! ......... some of

these boards took 45 to 65 years to grow one inch .........

this wood should (and is) be cherished.

|

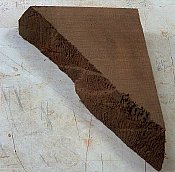

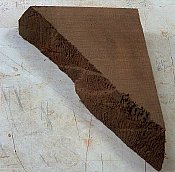

Here is the "END" of one of my boards ....

you can see that the tree was fallen over 125 years ago by

an AX

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

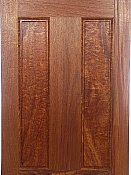

This Fir log was left at a log deck to rot ......

but we saved it and it made the most beautiful panels I've

ever seen.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The road to MendocinoDoos.com. I am bordered by

30,000 acres of Jackson State Redwood Forest

|

I save every usable scrap ....... I have a problem

!

|

Some Redwood doors ready to oil

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Every time a new shipment comes in, I travel 3 hours

to the "big city" and go through a few thousand board feet

of White Oak to pick those special pieces I want for my

doors

|

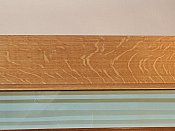

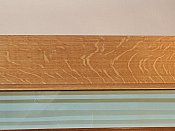

This is vertical grain ....... each line is an

annual growth ring. If the tree grows slowly the growth

rings are tight ........ as you see hear

|

Here is more high quality quarter-sawn White

Oak

|

The small stack is what I'll keep

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Each board is inspected and chosen for color,

denseness, and quality.

|

I buy only Select grade

|

I will go through 2-4 of these units just to find

the wood I use for my doors

|

The wood is stored in tightly covered units in dry

sheds on my land

|

|

|

|

|

|

|

|

|

|

|

Here is a flaw that can occur is white Oak. It is

called cellular collapse. It can not be seen from the

outside ... but if I cut the board open and find it , I

reject the wood and machine some other.

|

I will sometimes seal the excess machined wood in

plastic tubes to seal out the dust and humidity

|

absolutely vertical grain is known as Quarter-Sawn

lumber

|

My wood is cured in a heated room before it is

machined

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and then it is allowed to settle down and

stabilize

|

When the Oak is cut perfectly vertical,

medullary rays appear in the Oak

|

|

White oak medullary rays

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

My stops are solid White oak and are attached with

stainless steel fasteners

|

|

Look at the beautiful grain

|

My assistant lumber buyer !!

|

|

|

|

|

|

|

|

|

|

|