|

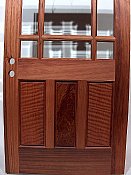

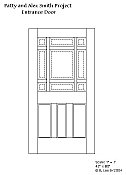

Here are two new doors I have just completed. |

|

|

|

|

|||

|

|

|

|

|

|||

|

|

|

This is the Sun Room Door |

|||||

|

|

|

|||

|

|

|

|

|||

|

|

|||||

|

|

|||||

|

|

|

|||

|

|

|

||||

|

|

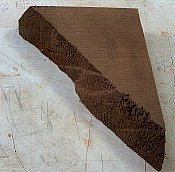

This is how these doors were constructed

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Click on ANY |

Image to Enlarge |

|||

|

|

||||

|

|

|

|

|

|

out of clamps |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Click on ANY |

Image to Enlarge |

|||

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

The panels will each be oiled with 4 coats of my "varnish oil" before they are placed in the door. |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

Most of our exceptional fabricated glass products have been constructed by Thermal Sun Glass of Santa Rosa, CA |

|

||

|

|

|

|||

|

Click on ANY |

Image to Enlarge |

|||

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||

|

Click on ANY |

Image to Enlarge |

|||

|

|

||||

|

|

|

|

|

|

|

|

|

Note: the stops are set with stainless steel fasteners so they won't "bleed out" rust over time. |

|

|

|

|

||||